I’m a little behind apparently in reporting this story – but it’s important, so I wanted to share it.

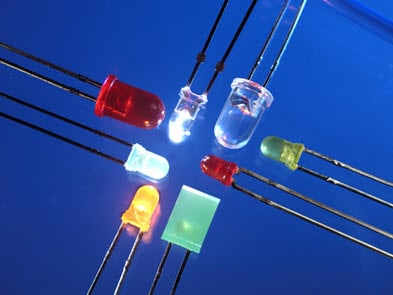

A material called Gallium Nitride (GaN) is something used in the making of LEDs. LEDs are “grown” on a substrate, and until very recently, this process and the materials used in the process have been very, very costly – driving the cost of some LED replacement lamps from $28 to over a hundred bucks each, some cases more, some less. But wow! You can buy a pack of 5 CFLs (despite them not being the highest quality) for about 7 bucks.

One of the price factors in this cost is the growing of these LEDs – which, instead of using something like silicon, uses sapphire. Gallium Nitride cools twice as fast as silicon, which creates failures and cracking in the manufacturing process. Sapphire has a cooling rate similar to that of GaN and the other LED compounds, which has made sapphire a standard in LED production.

Scientists and researchers at the University of Cambridge in England have developed an LED lamp that is three bucks – and is about 12 times more efficient than a typical tungsten incandescent lamp. They’ve determined a way to grow LEDs on silicon wafers using Aluminum Gallium Nitride layers, which cool slower and make this process a heck of a lot cheaper. The figure is that a 15cm wafer of silicon costs about $15, and can accomodate about 150,000 LEDs. How’s that for driving down the production price?

This LED has a projected life of about 100,000 hours.

The man we have to thank for this is Colin Humphreys, Emeritus Goldsmiths’ Professor of Materials Science at the University of Cambridge. More on this as it develops! I’m told we might see these on the market in as little as two years!

Thanks to Gizmodo, New Scientist, and EcoGeek!